Application Examples of Super Resin’s Epoxy Foam

-

Electronics

Cases that Realize Extremely Low-weightsThe cases used for laptop computers, smartphones, and other portable electronics prioritize ease-of-use as part of daily life, so must be lightweight and shock-resistant.

Given its unique ultra-thin and free-form molding capabilities, our epoxy foam can be molded into parts that are less than 1 mm thick, curve, and have local thickness variations.

We utilize an integrated molded structure consisting of foam cores and CFRP in order to produce electronics cases that are lighter and more shock-absorbent than conventional models. -

Audio Equipment

Micro Speaker DiaphragmsAudio equipment speaker diaphragms serve the role of vibrating and emitting sound waves in response to an electrical signal. High heat resistance and a high specific modulus are required to improve performance.

We can meet these requirements by combining our lightweight, ultra-thin moldable epoxy foam with highly elastic materials. Our epoxy foam lineup also includes a high heat resistance grade with a glass transition temperature of 180℃. -

Drones

Propeller GuardsPropeller guards are an important part of a drone that prevents the propellers from coming into contact with and becoming damaged by obstacles. When considering battery life, however, designs must avoid every excess gram of weight.

Our epoxy foam can be molded into complex 3D shapes without machining, which enables it to significantly reduce the weight of curved propeller guards. These guards have already been used in practice on large industrial drones. -

Sporting Goods

Cutting-edge Sports GearOur epoxy foam offers superior performance in terms of the lightweight, free-form, shock-resistance (shock absorption), and other properties required of sporting goods.

Our epoxy foam is ideal for realizing cutting-edge sports gear that maximizes the user’s performance unlike anything else in the world. -

Automobiles

Next-generation Automobile Structural ComponentsEfforts are under way in the automotive sector to replace metals with materials like CFRP in order to save energy.

Using our epoxy foam as a core material provides shock absorption and shortens the manufacturing process. Our epoxy foam can also provide various properties to automobile structural components that cannot be achieved with metals or CFRP alone. -

Industrial Machinery

Next-generation Industrial Machinery Structural ComponentsDepending on the application, industrial machinery requires lightweight, shock-resistance (shock absorption), high heat resistance, thermal insulation, sound insulation, and other such properties.

We flexibly combine our epoxy foam with metals and fiber reinforced plastics (CFRP/GFRP) to produce optimized hybrid structures. -

Others

World-first Product ComponentsBy adding new functionality to our epoxy foam, which excels in terms of its lightweight, free-form, shock-resistance (shock absorption), and other properties, as well as by molding the foam together with other materials, we can apply epoxy foam in the medical device, optical, aerospace, and various other sectors.

Characteristics of Super Resin’s Epoxy Foam

Our unique epoxy foam can freely form ultra-thin shapes and 3D shapes that cannot be achieved with conventional foam cores without cutting. Furthermore, it is possible to add new functionality and integrally mold with different materials such as CFRP.

Please click the contents to learn more details.

-

Variable Thickness Molding

Variable Thickness Molding

- Variable Thickness Molding

-

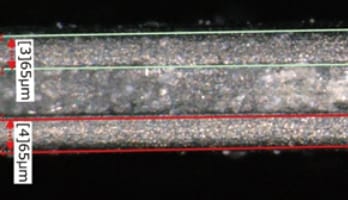

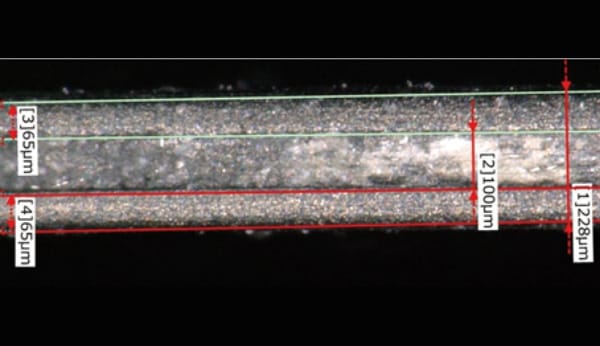

Our epoxy foam can also cope with the rapid and localized thickness changes that occur in molded products, something that presents a challenge for conventional foams. For example, we can mold continuous forms in which the thickness can vary from a maximum of 1 mm to a minimum of 0.1 mm.

-

3D Molding

3D Molding

- 3D Molding

-

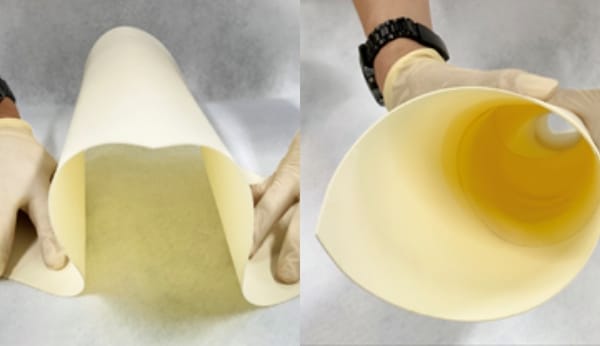

Through foam resin and process development, we are able to deliver foam that conforms to the geometry of complex uneven and curved surfaces when expanded inside the mold.

We thereby enabled in-mold forming of 3D (complex) foam shapes that could only be achieved by machining until now.

Eliminating the need for machining contributes to lower costs.

-

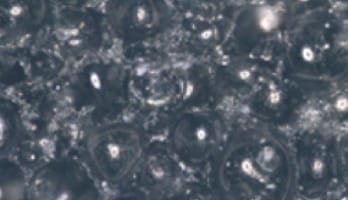

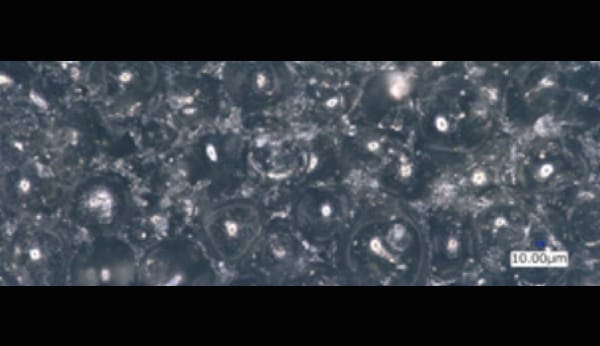

Ultra-thin Molding

Ultra-thin Molding

- Ultra-thin Molding

-

We can mold ultra-thin foam as thin as a few dozen microns. By combining ultra-thin molding with variable thickness and 3D molding, we can produce finer, more complex forms.

-

Thermal Deforming

Thermal Deforming

- Thermal Deforming

-

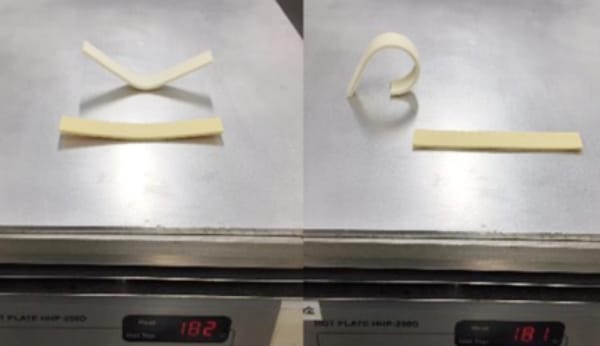

Thermal deforming can be applied at temperatures above the glass transition temperature. This approach enables us to deform our epoxy foam into the desired shape, which then maintains its deformed state when returned to room temperature.

Despite being a thermosetting resin that results in a hard foam, we provided our epoxy foam with thermal deformation characteristics like those of thermoplastic resins.

-

Flexibility

Flexibility

- Flexibility

-

Although our epoxy foam displays the physical properties of hard foam, it also has extremely high flexibility (shape memory).

-

High Heat-resistance

High Heat-resistance

- High Heat-resistance

-

In addition to the 130°C grade, we also offer a grade of epoxy foam with higher heat resistance specifications of 180°C. Please contact us if you wish to use our epoxy foam in higher temperature environments. When placed on a 180°C hot plate, standard foam will undergo thermal deformation, whereas high heat-resistant foam remains largely unchanged.

-

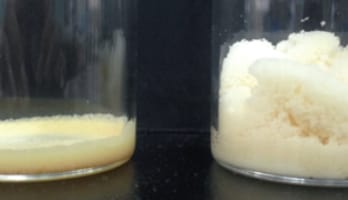

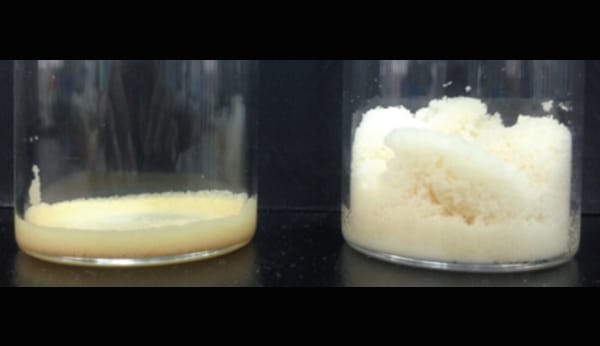

Expansion Ratio Control

Expansion Ratio Control

- Expansion Ratio Control

-

We can control the expansion ratio with high precision. In addition to the basic specifications, we can also meet our customers’ requirements for thickness and expansion ratios.

-

Functionalization

Functionalization

- Functionalization

-

The desired filler can be added at the resin synthesis stage During the raw material production stage, we can add strengtheners, fillers, and other additives according to the purpose in order to improve the mechanical properties of and impart functionality to our epoxy foam.

-

Integrated Molding with CFRP and Other Materials

Integrated Molding with CFRP and Other Materials

- Integrated Molding with CFRP and Other Materials

-

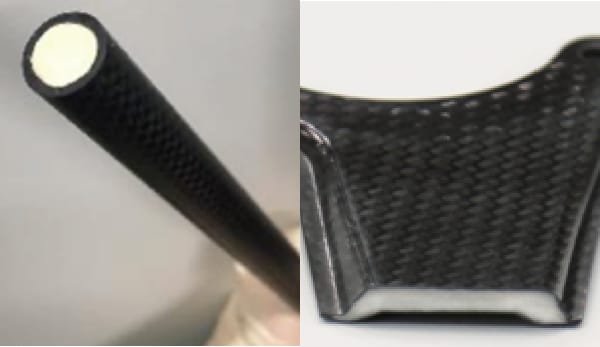

Epoxy foam can also be uniformly expanded and molded into the form of long, narrow pipes We can produce integrated molded products using CFRP as the surface layer and epoxy foam as the core. Because the basic composition of the foam is epoxy resin, it has good compatibility with CFRP and provides strong adhesion without using adhesives.

Our epoxy foam also exhibits strong adhesion against aluminum and other metals because it is made from epoxy resin, which is widely used as an adhesive.

Properties of Tg130℃-Type Epoxy Foam

| Density (Kg/m3) | 240 | 120 | 60 | |

|---|---|---|---|---|

| Tensile Test Result |

Strength (MPa) | 3.5 | 2.1 | 0.6 |

| Elastic Modulus (MPa) | 103.4 | 63.4 | 23.7 | |

| Elongation (%) | 7.4 | 7.7 | 5.0 | |

| Compressive Test Result |

Strength (MPa) | 3.3 | 1.2 | 0.4 |

| Elastic Modulus (MPa) | 120.8 | 53.1 | 28.5 |

*The table above shows the physical properties of the epoxy foam of which glass transition temperature (Tg) is 130℃.

Specifications for Reference

| Foaming Rate=5 | Foaming Rate=10 | Foaming Rate=20 | |

|---|---|---|---|

| Thickness=1mm | ○ | ○ | Developing |

| Thickness=2mm | ○ | ○ | ○ |

- Foaming Rate and Specific Gravity

-

- Foaming Rate=5 — 240kg/m3 (equivalent to 0.24g/cm3)

- Foaming Rate=10 — 120kg/m3 (equivalent to 0.12g/cm3)

- Foaming Rate=20 — 60kg/m3 (equivalent to 0.06g/cm3)

Development Contracting

- Epoxy Foam Development Contracting Services

- In addition to the above specifications, we also accept special requests (thickness, expansion ratio, CFRP-integrated molding, etc.).

We handle development to propose the best solutions tailored to our customers’ requirements. Please feel free to contact us at any time.

Inquiries regarding Epoxy Foam

For sample requests and inquiries regarding quotes, products, and technologies, please use the following form.